CAPACITIVE SENSORS ARE SUITABLE FOR A VARIETY OF APPLICATIONS. IN THE COMET PROJECT “DIMO”, A TEXTILE CAPACITIVE SENSOR IS BEING INVESTIGATED FOR MEASURING RESPIRATION, IN PARTICULAR RESPIRATORY RATE AND FLOW REVERSALS. FOR THIS PURPOSE, THE TEXTILE SENSOR IS INTEGRATED INTO A CHEST STRAP AND EVALUATED VIA A SUITABLE ELECTRONIC CIRCUIT.

The integration of sensors in clothing opens up new fields of application, and the new materials and technologies pose new challenges for research and development. For example, sportswear in particular must be washable, and sensors in clothing must therefore be able to withstand many washing cycles. Capacitive sensors are relatively robust, but they are also more difficult to evaluate than the resistive sensors (“strain gauges”) normally used. Moisture, especially sweat, can be another problem.

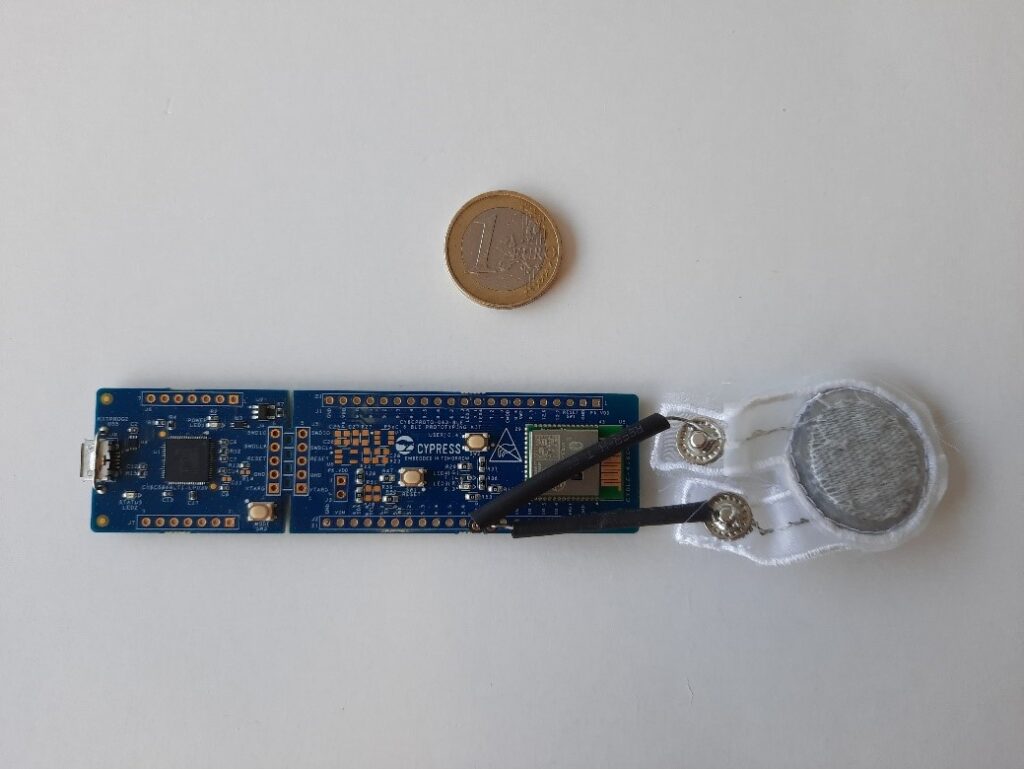

A suitable measurement technology for determining the capacitive measurand is provided by Infineon with its CapSense® technology. With this technology, integrated in Infineon’s PSoC™ MCUs, a very accurate conversion of a capacitive measurement value into a binary code is possible. An early prototype of this circuit is shown in Figure 1.

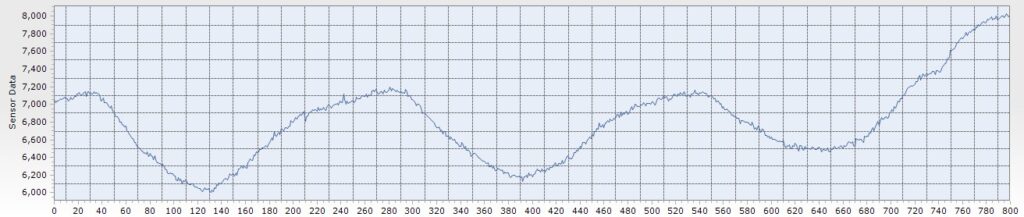

The measurement method allows very high sampling rates, as well as several parallel input channels, and thus the determination of different measurement values simultaneously. This is due to the flexible analog front end of the PsoC. Figure 2 shows the measured value for three breathing cycles as an example.

The acquired signal is filtered and evaluated using signal processing and statistical methods. This allows the respiratory rate and the points of flow reversal, i.e. the points of change between exhalation and inhalation, to be calculated from the signal.

Figure 2 Sensor raw signal: three breathing cycles

The investigated technology and the resulting prototype – integrated into a chest strap – will be used for further research and studies. For example, the investigation of the coupling of the respiratory signal to other biophysical signals during activity (e.g. heart rate) as well as biofeedback (e.g. by means of visualization) are planned. Further development of the technologies for later product developments is also planned.